The Downsides of a Bed-in-a-Box Mattress: What to Know Before You Buy

Last modified on:

What is a Bed-in-a-Box?

A bed-in-a-box is exactly what it sounds like: a mattress that’s compressed, rolled, and vacuum-sealed into a box for convenient shipping.

It’s designed to be easily shipped to your door and set up without the need for a delivery team.

Over the last decade, bed-in-a-box mattresses surged in popularity thanks to their convenience, competitive pricing, and heavy marketing from both big brands and newer players in the mattress space.

They’re often sold direct-to-consumer online, bypassing traditional mattress stores.

The Rise of Bed-in-a-Box Popularity

Their popularity is fueled by several factors:

However, as with many trends, there’s more to the story than meets the eye.

Let’s dive into some of the key drawbacks of bed-in-a-box mattresses that you should consider before clicking ‘add to cart.’

The Drawbacks of Bed-in-a-Box Mattresses

Compressed Construction Can Impact Longevity

To fit into a box, these mattresses are compressed, often for weeks or even months during transit and warehouse storage.

This compression can compromise the integrity of the materials, particularly lower-density foams, and may result in premature sagging or reduced support over time.

Off-Gassing and Odor

Most bed-in-a-box mattresses use synthetic foams, which can emit a strong odor (often called “off-gassing”) when first unwrapped.

It can be unpleasant, particularly for those who are sensitive to smells or have allergies.

Lighter Materials May Mean Less Support

One of the biggest differences between locally-sold traditional mattresses and bed-in-a-box mattresses is their weight and the materials used.

Let’s break it down:

Locally sold, heavier mattresses prioritize durable, dense materials for long-lasting support and comfort.

Bed-in-a-box models, on the other hand, emphasize portability and lower shipping costs, sometimes at the expense of support and lifespan.

Many bed-in-a-box models still can’t match the robust construction of their traditional counterparts.

How Mattress Weight Impacts Material Choices

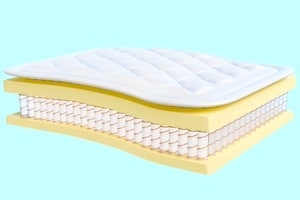

The significant difference in weight between locally sold and bed-in-a-box mattresses is primarily due to the materials used in their construction.

Traditional Mattresses

(mostly locally sold)

Denser Materials:

Traditional mattresses often incorporate denser materials that add to their weight and durability.

For instance, they may use high-density foams, such as high-density polyurethane or memory foam, which are heavier but provide superior support and longevity.

Many also feature natural latex, particularly Dunlop latex, renowned for its density and resilience.

Additionally, robust coil systems in innerspring and pocketed coil mattresses often utilize heavier-gauge steel coils, enhancing support and motion isolation.

Construction:

Traditional mattresses often feature construction elements that add to their weight and overall durability.

Thicker comfort layers provide more support and pressure relief, while additional support layers enhance the mattress’s capacity to maintain comfort and durability, especially for heavier individuals.

Reinforced edges and pillow tops also contribute to a more stable and luxurious feel, although they naturally add to the mattress’s weight.

Bed-in-a-Box Mattresses (shipped compressed)

Lighter Materials:

Bed-in-a-box mattresses often rely on lighter materials to achieve their compact, compressible design, which makes shipping and handling easier and more cost-effective.

For instance, they typically use lower-density foams, such as polyfoam and memory foam, that are easier to compress and package tightly.

While these materials can still offer comfort, they may sacrifice some of the long-term support and durability provided by denser foams found in traditional mattresses.

Hybrid models in this category also use coil systems, but these are usually designed to be lighter and highly compressible for shipping, often featuring fewer coils overall.

Construction:

Bed-in-a-box mattresses often feature simplified layer structures that prioritize easy compression for shipping, which means they must comply with strict weight and size limits set by carriers like USPS, UPS, and FedEx.

By using fewer layers overall, manufacturers can reduce both the bulk and weight of the mattress to stay within standard parcel shipping thresholds, typically under 70 pounds for USPS and 150 pounds for UPS/FedEx.

These design choices keep shipping affordable and avoid freight surcharges, but they often come at the cost of robust support and long-term durability.

Additionally, thinner comfort layers are used to minimize both weight and volume, which can compromise the mattress’s pressure relief and overall lifespan compared to more traditional, locally sold models.

In Summary:

Locally sold, heavier mattresses prioritize materials like dense foams and robust coil systems for increased support, durability, and a more substantial feel, often allowing for thicker profiles and additional comfort features.

Bed-in-a-box mattresses, designed for compressed shipping, tend to use lighter, more compressible materials (like lower-density foams), which helps keep shipping costs down.

This can impact the overall lifespan and support of the mattress, though technological advancements are constantly improving the quality of materials used in bed-in-a-box mattresses.

Limited Edge Support

Many bed-in-a-box mattresses (especially all-foam models) struggle with edge support, meaning you might feel like you’re sliding off the mattress when sitting or sleeping near the edge. This can affect usable sleep space and overall comfort.

Heat Retention

Because many bed-in-a-box models use lower-density foams and simplified construction, they sometimes lack the advanced cooling features found in higher-end traditional mattresses. This can lead to heat buildup, making sleep less comfortable for hot sleepers.

One-Size-Fits-Most Approach

Most bed-in-a-box brands offer a single or limited range of firmness options, often aiming for a ‘universal comfort’ feel. This can work for some people, but others (especially those with more specific sleep needs or preferences) might find it challenging to get the perfect fit without trying before buying.

Warranty & Return Hassles

While bed-in-a-box companies often advertise generous return policies, returning a compressed mattress can be awkward and time-consuming. You might be responsible for repackaging it, coordinating a pickup, or showing proof of disposal.

The DIY Mattress Solution

One of the many benefits of a DIY mattress is that the components all come in separate boxes, so the fully assembled weight of the mattress is never a shipping concern.

This means DIYers can take advantage of the same high-quality, denser materials found in locally sold, heavier mattresses (like natural latex, high-density foams, and robust coil systems) while still enjoying the convenience of ordering online and assembling at home.

Plus, DIY mattress builders can often keep costs down by skipping the high overhead of traditional mattress stores and their delivery and setup teams.

In other words, with a DIY approach, you can get the best of both worlds: premium materials, a fully customizable sleep experience, and the convenience of home delivery, without compromising on quality or comfort.

Drawbacks

While bed-in-a-box mattresses have revolutionized the convenience and accessibility of mattress shopping, they’re not without their drawbacks.

Trade-offs

Understanding the trade-offs, especially around materials, construction, and support, can help you make a more informed decision.